URBNC – 10,000x Speed Up in AI-Driven Custom Footwear (CTO)

Single-handedly developed the full digital pipeline with AI algorithms for customized insoles

URBNC3 — Custom Footwear Technology

I joined URBNC3 in Switzerland as a technical co-founder after initially contributing to the engineering side of the project. The goal was straightforward yet ambitious: turn a person's unique foot shape into a custom supportive insole or sandal base by using digital technology.

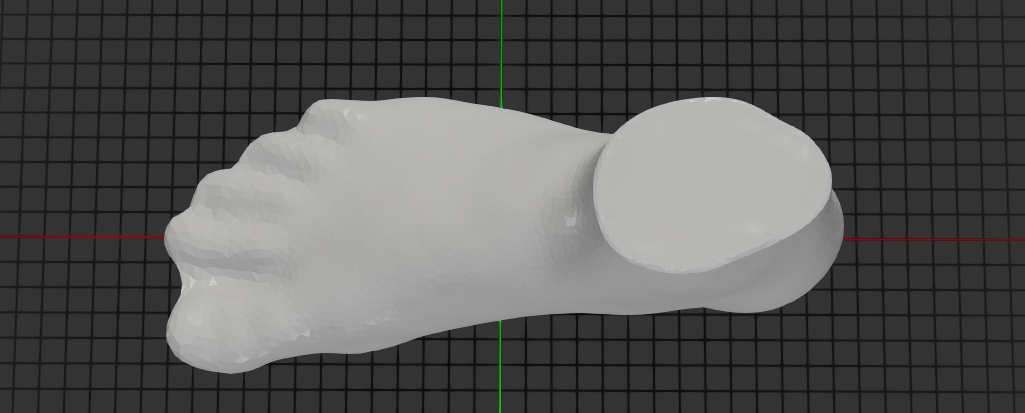

Normal shoes come with flat insoles that are the same for everyone. But very few people have identical feet. With URBNC3 we asked what it would take to provide the right support for every foot. The process was built around capturing multiple photographs of a foot from different angles using a mobile app, reconstructing a 3D model of that foot through an API, then running mesh processing and feature-extraction algorithms to generate a print-ready insole or sandal base. My focus was on the part after the model: converting the foot model into a printable support mesh that combined comfort, posture-correction and manufacturing readiness.

My Role and Achievements

Contributed as technical co-founder with primary responsibility for the insole mesh pipeline, alongside the founding team.

Developed a 3D object library and mesh processing code that reduced design time from roughly four to five hours down to about one point five to two point five seconds on a standard laptop.

Engineered automation workflows and APIs to support conversion from digital model to physical print file.

Wore the beta insoles regularly and found them among the most comfortable footwear I own.

Project Status

The foundational technology pipeline was completed and entered prototype testing phases. While the physical production pipeline was not fully scaled, the project stands as a meaningful example of turning code into something people can wear.

References

- ETH Zurich: From student project to personalised sandals from a 3D printer

- ETH Zurich: Twitter showcase post (X)

- TechBriefs: 3D printing sustainable footwear

- Unsustainable Magazine: The footwear revolution

- ETH Student Project House: URBNC3 Project Page

- TrendHunter: URBNC3 Modular Sandals

- Additive Manufacturing Network: Customised shoes and sandals with 3D printing

- Moneycab: Modular vegan sandals based on smartphone scans

- Faircustomer: Interview on URBNC3 Approach

- ETH Partnerships: Personalized sandals from the 3D printer

- Swiss Textiles: Innovation Booster winners recognition

- LifeVerde: Sustainable footwear design feature

- 3Dnatives: Individualized footwear through 3D printing

- WPK: Swiss innovation coverage

- Prestige Business: Spotlight on URBNC3

- Sustainability Challenge: Final Projects 2023